Main Subjects = Production

Number of Articles: 34

The Effect of Infill Pattern on Tensile Strength of PLA Material in Fused Deposition Modeling (FDM) Process

Volume 40, Issue 12 , December 2022, , Page 1723-1730

Abstract

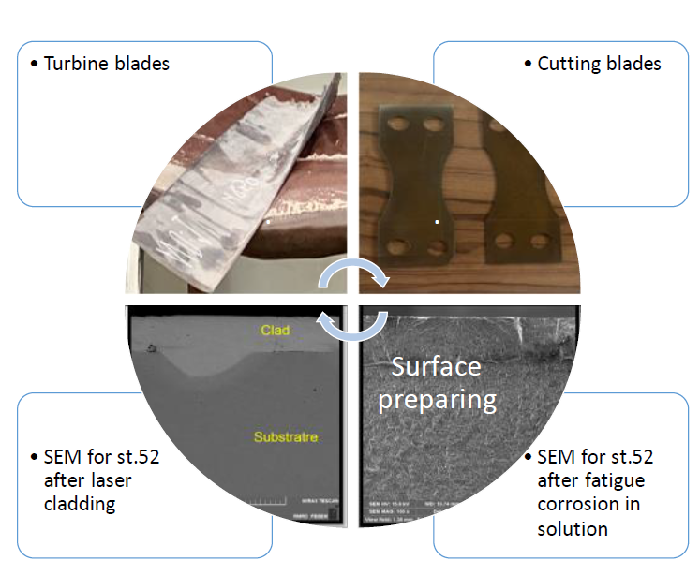

Fused deposition modeling (FDM) is an additive manufacturing (AM) process often used to build geometrically complex prototypes and parts. It is becoming more popular since it improves ... Read More ...Improving Fatigue Corrosion Resistance of Turbine Blades Using Laser Processing

Volume 40, Issue 12 , December 2022, , Page 1765-1774

Abstract

The present paper investigates the nanomaterial coatings effect on turbine blades by laser processing. The present paper explores the impact of laser cladding parameters on the corrosion ... Read More ...Supplier Ranking in Dental Sector Using Integrated Fuzzy (AHP-TOPSIS)

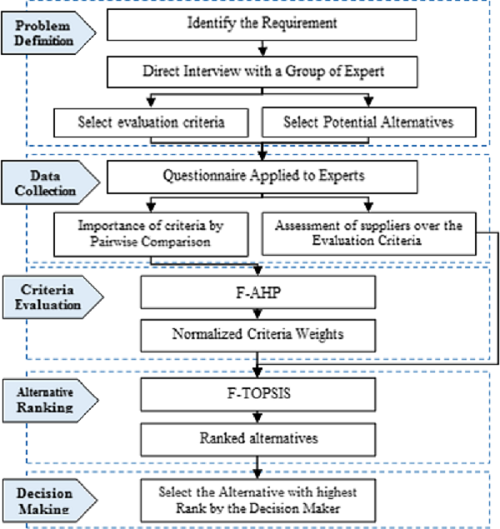

Volume 40, Issue 12 , December 2022, , Page 1775-1782

Abstract

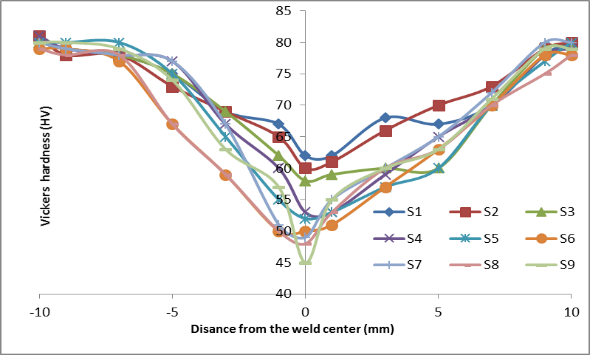

Choosing a suitable supplier of materials and equipment in the healthcare sector is essential because it directly affects the patient's health and the organization's effectiveness and ... Read More ...Properties of Welded Copper Tubes Fabricated Via Friction crush Welding

Volume 40, Issue 6 , June 2022, , Page 840-847

Abstract

The welding process is one of the fabrication processes in which tubes can be performed for structural purposes and transport liquids or gases. This study is focused on the manufacturing, ... Read More ...Effect of Voltage on Electrode Wear Rate (EWR) in the Electrical Discharge Machining (EDM) for Stainless Steel AISI 444

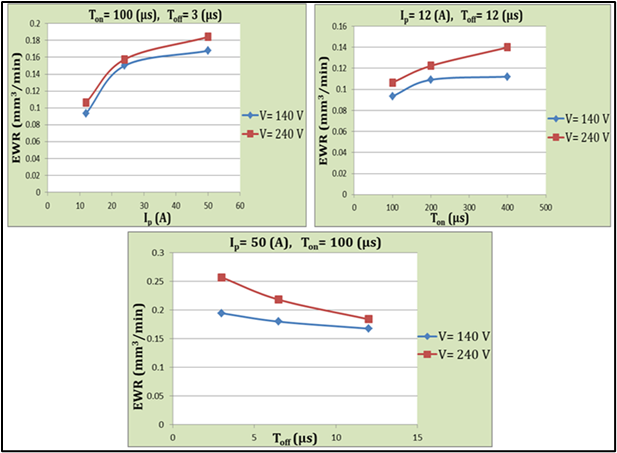

Volume 40, Issue 6 , June 2022, , Page 21-30

Abstract

Electrical Discharge Machining process (EDM) is a nontraditional metal removal technique that uses thermal energy to erode the workpiece without generating any physical forces of cutting ... Read More ...Improvement of Metal Forging Processes by Stresses and Temperatures Analysis

Volume 40, Issue 6 , June 2022, , Page 869-878

Abstract

The mechanical components are produced by various fabrication methods, although forged products have excellent mechanical characteristics at a minimal cost. The stress and temperature ... Read More ...Influence of Machining Parameters on Surface Roughness in Chemical Machining of Silicon Carbide (SiC)

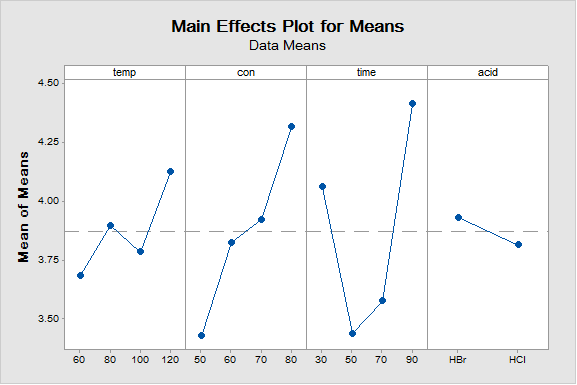

Volume 40, Issue 6 , June 2022, , Page 879-884

Abstract

This study discussed the influence of chemical machining parameters such as (machining time, type of etchant, etching temperature, and concentration of the solution) on the surface ... Read More ...Effect of Abrasive Water Jet (AWJ) Parameters on Materials Removal Rate for Low Carbon Steel

Volume 40, Issue 6 , June 2022, , Page 885-891

Abstract

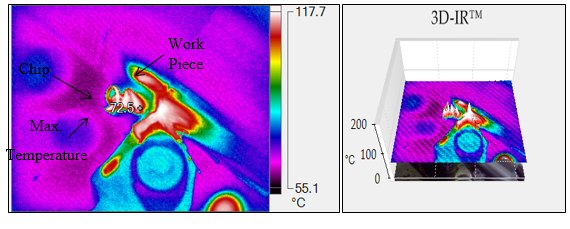

Abrasive water jet (AWJ) is one of the most advanced and valuable non-traditional machining processes because of its massive advantages of removing metal from hard and soft metals. ... Read More ...Studying the Effect of un Coated and Multilayer Coated Tools on Cutting Temperature in Turning Operation

Volume 40, Issue 6 , June 2022, , Page 911-917